Got a question you need answered? Get in touch!

Brewing questions? We can help, get in touch today!

Spend less time washing bottles and more time enjoying the fruits of your labour. Kegging systems are an awesome way to; save time that would be spent bottling, shorten carbonation time, minimise oxygen exposure, get clearer beers using fining agents and much much more. The following post covers (in order):

- What you need to start kegging

- Assembling a kegging setup

- Using bayonet (barbs and clamps) fittings

- Using Speed fittings (Duotight/John Guest)

- Pressure testing gas lines/leak detection

- Transferring Beer to kegs

- Purging kegs

- Carbonating Beer

- Dispensing Beer

- Troubleshooting issues

- Why your pouring foam

- Beer carbonation issues

- How to check how full your CO2 bottle is

- CO2 bottle

- CO2 regulator

- Gas line

- Gas ball lock disconnect

- 19L Cornelius style ball lock keg

- Liquid ball lock disconnect

- 3m beer line

- Pluto gun/picnic tap/tap

- A fridge to keep your keg and kegging setup in - most household fridges with the shelves removed work perfectly for this.

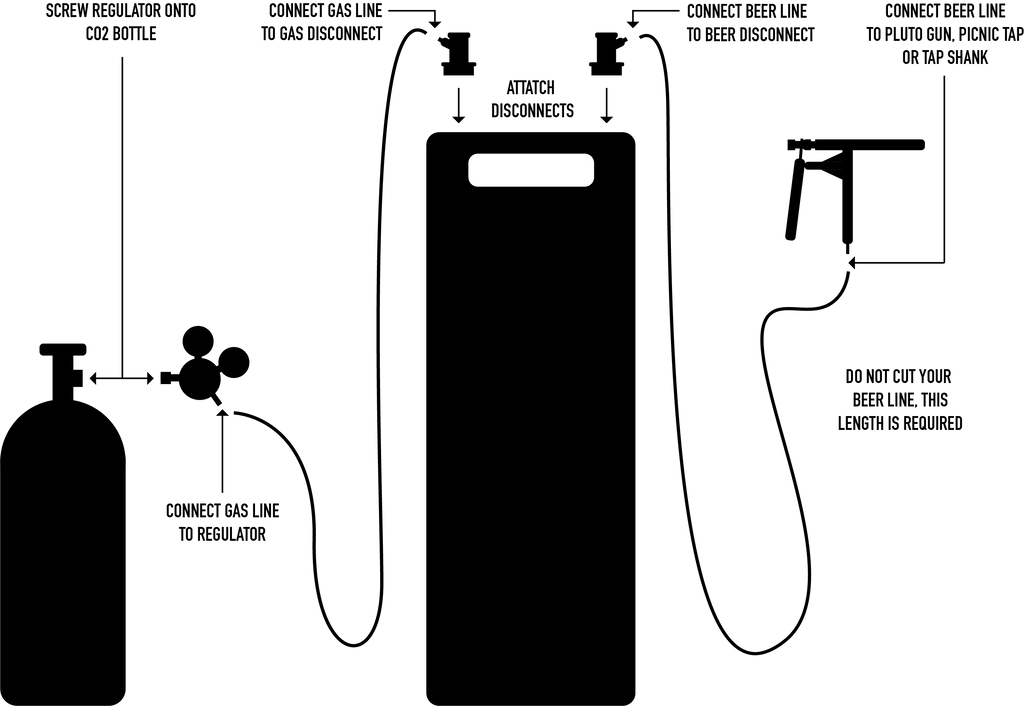

**Your starter kit may come with push in fittings or barbs and clamps depending on the kit you end up purchasing. This will dictate how your beer and gas tubing is connected to the other keg fittings. Regardless of the style of fitting the principle is the same and can be seen clearly in the diagram below.

Below is a diagram of a basic kegging setup to help you visualise the system.

1. Attach the co2 regulator to the co2 bottle; ensure to screw the regulator down nice and tight to compress the nylon washer. Thread tape is not necessary.

2. Attach your gas line to the regulator and gas disconnect. More info on connecting your gas and beer line is outlined in the next section.

3. Attach your beer line to your dispensing unit (pluto gun, picnic tap, or tap shank)

4. Connect your gas and liquid disconnects to the corresponding keg posts (these are labeled on your keg). Beer Disconnects are black and Gas Disconnects are grey. A handy tool to remember this is; B for Beer, B for black and G for gas, g for grey.

1. Use warm water to soften the tubing before attempting to slide it over your barb

2. Needle nose pliers can be inserted into your tubing and used to widen the lumen so it fits over your barbs

3. Attach the clamp halfway up the barb and ensure to clamp down with a good amount of force

1. Ensure the tubing is cut using a sharp blade to produce a clean cut that is perpendicular to your line

2. Ensure the tubing is free of abrasions and scuffing where the tubing will enter the speed fitting

4. Ensure the tubing is pushed all the way into the fitting

5. Simply push the line in and your’e ready to go!

1. Disconnect your grey disconnect from your keg

2. Turn your co2 bottle on using the valve located on the top of the bottle.

3. Turn the pressure on your regulator to 30psi by turning the dial clockwise.

4. Turn off your co2 bottle using the valve located on the top of the bottle.

5. Make a note of the pressure and come back in 2-3 hours.

6. If the pressure is lower than when you left there is a leak in the gas line somewhere. In this case you need to identify the leak and perform the pressure test again. This can be done by submerging the line and disconnects in water and look for bubbles or spraying any connection points with soapy water.

1. Sanitise the keg and beer lines using sodium percarbonate or your chosen steriliser.

2. Empty the keg of the steriliser and rinse (if using a steriliser that requires rinsing)

3. Flush the keg with co2 by attaching the gas disconnect and running co2 through the keg at a low pressure for a few minutes. Vent the pressure using the pressure release valve on the keg lid. After a minute or two remove the gas disconnect.

4. Take a tube from your fermenter tap and sanitise it

5. Open the keg after releasing the pressure using the keg lid.

6. Attach your tubing to your fermenter tap and put the line into your keg so it sits on the bottom

7. Open the tap and fill your keg until it is filled to 1-2cm below the gas dip tube (the tube that comes out of the bottom of your gas post). Any higher and you risk beer travelling up your gas line and into your regulator which can damage the product or cause it to fail.

8. Remove the transfer tube and reseal the lid, ensure the lid sits flush.

9. Reattach the gas disconnect and flush the headspace of the keg with co2 in the same way as step 3.

10. Your keg is now full and ready for carbonation.

When using a kegging system we can use high pressures to force CO2 to dissolve into our beer. This is known as force carbonation. Force carbonation can be done in a number of ways - here we will outline the simplest way with the least margin for error. We highly recommend carbonating your beer when the beer is already cold as this will make for a more efficient carbonation process. As we can see in the diagram on the right as temperature co2 decreases solubility increases. This can be demonstrated by opening a warm can of beer vs a cold one. A warm beer froths up when opened while an ice cold beer doesn’t. This is due to co2 coming out of solution at different rates due to changes in temperature. This same principle can be applied when we get to the troubleshooting section of this article.

Assuming the beer is already cold we can apply a pressure to the headspace of your keg and CO2 will begin dissolving. The rate at which co2 dissolves is dependent on the partial pressure of CO2 in the headspace. Given that most home-brewers will use 100% co2 the reading on the low pressure dial of our regulator will be the same as the partial pressure of co2. The chart below is a general guideline on carbonating. Ensure your co2 bottle in on and set to the right pressure when carbonating.

1. Chill beer inside your keg to a few degrees celsius

2. Attach your gas disconnect to the keg and turn the pressure up to the level you desire, referring to the diagram below.

3. Keep the keg cold and the co2 bottle connected and at the carbonating pressure you have selected for the corresponding amount of time listed with your pressure in the table below.

4. After that amount of time has elapsed disconnect your gas from the keg.

5. Gently pull the pressure release valve on the keg to release the carbonating pressure.

6. Turn your dial counterclockwise on your regulator until you feel the diaphragm under the dial disengage. This will indicate your regulator is not allowing any co2 to pass through.

7. Turn the regulator back up until the low pressure dial reads between 10 - 12 psi. This is your dispensing pressure.

8. Attach the grey disconnect to your keg and bring the pressure back up to serving pressure

9. You are now ready to dispense your beer!

|

CO2 PRESSURE (PSI) |

MEDIUM CARBONATION LEVEL |

HIGH CARBONATION LEVEL |

|

20 PSI |

5 DAYS |

7 DAYS |

|

30 PSI |

14 HOURS |

40 HOURS |

|

35 PSI |

12 HOURS |

30 HOURS |

|

40 PSI |

10 HOURS |

26 HOURS |

|

45 PSI |

8 HOURS |

22 HOURS |

1. Ensure your regulator is sitting at serving pressure (10-12 psi), this pressure is related to the carbonation level, dispensing or storing your keg will less pressure will cause co2 to come out of solution and drop the carbonation level.

2. Attach your liquid disconnect to the keg.

3. Open your tap and allow the beer to flow through

4. Enjoy the beers!

Once your keg is carbonated and set to serving pressure you can turn your co2 bottle off unless you are dispensing. Assuming the setup is leak free this is a closed system and will stay carbonated without the co2 bottle open. This helps to ensure you don’t empty a gas bottle with a slow leak too.

Keep your entire keg cold, 1-3℃ is ideal.

Make sure to clean your lines regularly

Every now and then disassemble your keg posts and take the keg apart to give it a thorough cleaning. Hops, trub and other material can get lodged in the poppet springs.

- Check the fridge temperature and ensure it is ice cold - we want to be as cold as possible without freezing kegs or beer lines.

- Ensure the lines are also cold

- Make sure your lines aren't frozen

- Check the beer line. We want the beer-line to sit above the keg and continue on an upward path. If not bubbles can form inside your beer lines. When beer is travelling fast and smashing into bubbles that have pooled in your beer lines it will cause more bubbles to come out of solution as the beer with dissolved co2 smashes into them.

- Ensure your lines are long enough. We recommend 3 metres for 5mm ID tubing and 2.5 for 4mm ID tubing.

- Ensure your dispensing unit is cold, tap head is cold, pluto gun is cold, ect. If beer travels through a warm tap or warm lines it will heat up, like we discussed earlier - CO2 is less soluble at warmer temperatures and will begin to come out of solution as the beer warm causing bubbles to form.

- Ensure the fridge is cold

- Double check your dispensing pressure

- Ensure your co2 bottle was turned on when carbonating

Unlike lpg and other compressed gases co2 bottles aren't actually filled by pressure. Instead they are filled by weight. The reason for this is that carbon dioxide turns into a liquid at around about 10 bar of pressure when it’s between 10 and 30℃. This means that instead of reading the total bottle pressure the high pressure gauge on our regulator is actually reading the vapour pressure of liquid co2. This vapour pressure is dependent on temperature. This means you bottle may look emptier on a cooler day that a hot day. The best way to check how full your co2 bottle is to tare the weight of your CO2 then weigh it again when you need to see how much CO2 is left.

Leave a comment